How an Optical Fibre Diameter Analyser Optimizes Manufacturing Accuracy

How an Optical Fibre Diameter Analyser Optimizes Manufacturing Accuracy

Blog Article

Maximize Your Fibre Optic Efficiency: Recognizing Optical Fibre Diameter Analyser Innovation

The performance of fibre optic systems is critically influenced by the accuracy of their size, an aspect frequently overlooked in the search of ideal signal honesty. Understanding the technology behind optical fiber diameter analysers discloses the detailed equilibrium between measurement accuracy and manufacturing quality. These devices not only boost conformity with market criteria however likewise provide real-time insights that can preemptively resolve possible issues. Nevertheless, the effects of their use expand beyond plain dimension; they can fundamentally change the landscape of fibre optic effectiveness. What factors should one consider to harness their complete possibility?

Importance of Optical Fibre Diameter

The size of optical fibre plays a critical duty in establishing the performance and performance of interaction systems. Conversely, smaller sizes tend to sustain less settings, which can improve signal clarity and decrease crosstalk.

Moreover, understanding the size's implications can bring about cost savings by decreasing the need for signal amplification and repeaters in comprehensive networks (optical fibre diameter analyser). To conclude, the importance of optical fiber diameter can not be overemphasized, as it directly impacts the general performance and dependability of modern-day interaction systems

Exactly How Diameter Affects Signal Quality

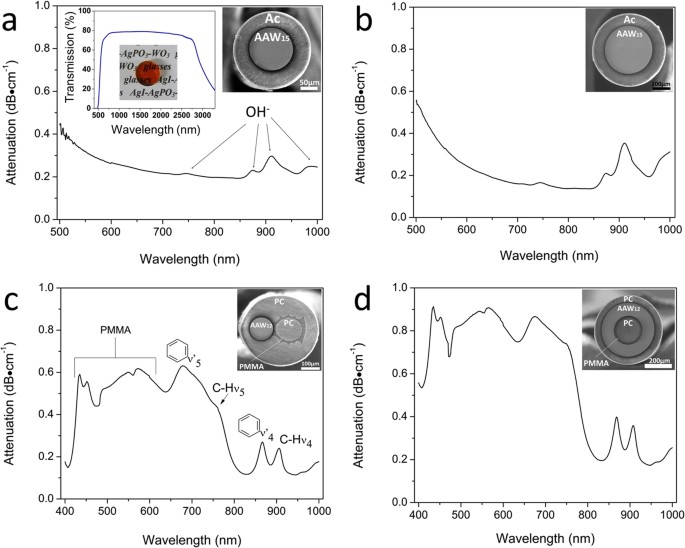

Signal top quality in optical fibre systems hinges significantly on the size of the fiber. The size affects several key specifications, consisting of attenuation, data transfer, and modal dispersion. A smaller sized size can bring about greater attenuation prices, causing signal loss as light journeys via the fiber. This attenuation can compromise the honesty of the transmitted data, causing a decrease in signal top quality, specifically over cross countries.

Alternatively, larger diameters usually enable boosted light capture and minimized modal dispersion, improving signal clearness. In multimode fibres, a bigger core size can sustain several light settings, but it might likewise present intermodal diffusion, which can break down signal high quality. For that reason, choosing the ideal fiber diameter is crucial for achieving the preferred performance in particular applications.

In addition, the communication between the fibre size and the wavelength of the light made use of plays an essential function in identifying the effective transmission range and general signal honesty. Thus, comprehending how fibre diameter affects signal high quality is important for network developers and designers making every effort to optimize optical fiber systems for dependable, high-speed data transmission.

Introduction of Size Analyser Modern Technology

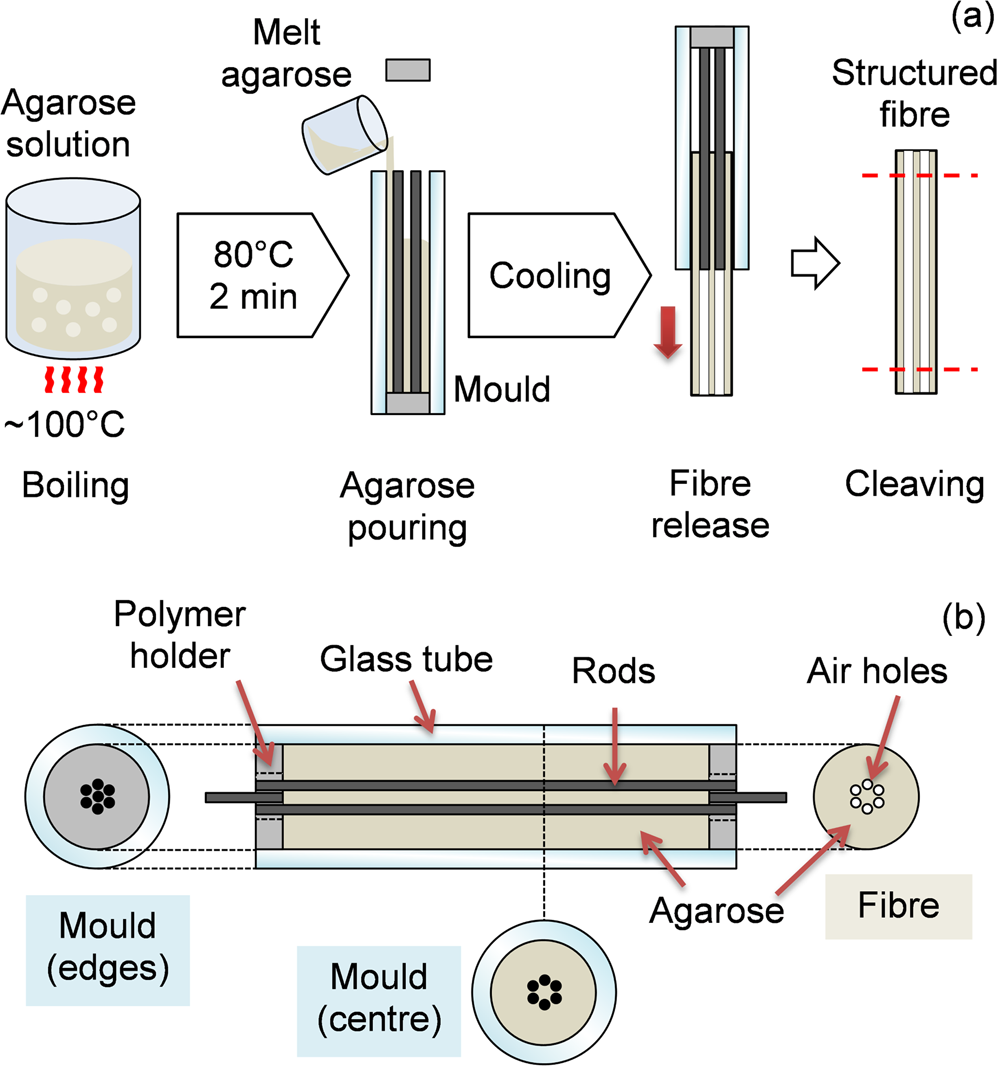

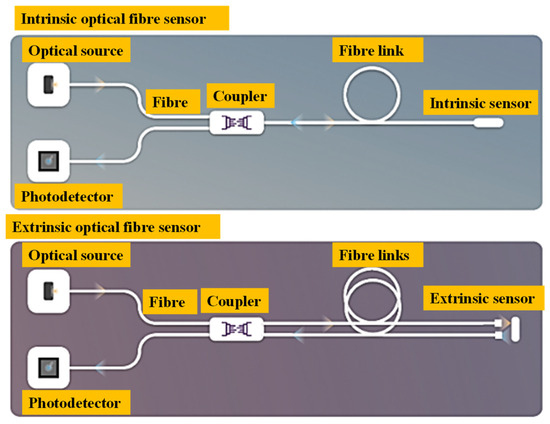

In several optical fibre manufacturing processes, accurate measurement of fibre diameter is important for guaranteeing consistent efficiency and high quality (optical fibre diameter analyser). Diameter analysers are advanced instruments made to assess the physical measurements of optical fibers with high precision. They use innovative optical and laser innovations to measure the diameter, ovality, and concentricity of the fiber, thus supplying important data for quality assurance

These analysers can run in-line throughout the production process or as part of off-line testing methods. In-line systems enable real-time surveillance, permitting manufacturers to readjust criteria right away, therefore preserving optimal manufacturing problems. Off-line analysers, on the various other hand, supply comprehensive assessments of sets, making certain that any deviations from specified resistances are determined and dealt with.

Diameter analysers significantly add to the reduction of flaws in optical fibres, enhancing total product integrity. By constantly measuring key parameters, these modern technologies help with compliance with market criteria and specifications. As the need for high-performance optical fibers continues to climb, the duty of diameter analysers comes to be significantly crucial in accomplishing the desired quality and performance criteria in fiber optic systems.

Key Functions of Fibre Diameter Analysers

Although different designs of fibre diameter analysers exist, they frequently share several key functions that improve their functionality and reliability. Among one of the most considerable attributes is high-resolution measurement abilities, which ensure specific size readings, vital for preserving high quality control in fiber production. Additionally, lots of analysers incorporate sophisticated optical sensing units developed to discover minute variants in fibre size, thus providing indispensable information for procedure optimization.

Another vital attribute is real-time tracking, allowing operators to receive prompt feedback on fibre size throughout the manufacturing procedure (optical fibre diameter analyser). This capacity promotes quick changes and reduces the chance of flaws. Numerous analysers additionally come outfitted with easy to use user interfaces, enabling operators to conveniently navigate with data and setups results

Additionally, durable data storage space and analysis capabilities are essential for tracking historical efficiency fads and making sure conformity with sector requirements. Some versions also offer connection choices for combination into existing manufacturing control systems, improving general operational effectiveness. Last but not least, portable and small styles permit versatile implementation within manufacturing settings, guaranteeing that quality control procedures are seamless and efficient. These attributes jointly add to the efficacy of fiber diameter analysers in enhancing fibre optic efficiency.

Ideal Practices for Fibre Optimization

First, routine calibration of optical fiber diameter analysers is essential. This guarantees exact dimensions and reduces potential disparities that could influence efficiency. Next, preserving a tidy working setting is crucial; dirt and contaminants can result in indicate deterioration.

Furthermore, it directory is essential to choose fibres that meet details application demands. This entails evaluating variables such as depletion, transmission capacity, and ecological problems. Proper setup methods should also be abided by, including staying clear of sharp bends and too much stress, which can endanger fibre honesty.

Furthermore, using sophisticated surveillance systems can help with real-time efficiency assessments, enabling prompt identification of problems. Regular testing and maintenance need to be performed to guarantee that fibers stay within ideal operational parameters.

Lastly, training personnel on the most recent fibre optimization technologies and techniques will certainly improve their capacity to carry out effective techniques. By complying with these finest practices, companies can considerably improve the efficiency and lifespan of their optical fiber systems, making certain effective communication and information transfer.

Final Thought

In verdict, the integration of optical fiber diameter analyser technology is critical for making best use of fibre optic efficiency. By guaranteeing precise measurements of fiber measurements, these analysers significantly boost signal quality and lower losses additional hints throughout information transmission. Normal calibration and upkeep of the analysers are vital to support optimal performance and conformity with industry standards. Inevitably, the application of Click This Link this technology assists in enhanced information transmission prices and enhances signal integrity, adding to the total effectiveness of fibre optic systems.

Signal top quality in optical fibre systems hinges dramatically on the diameter of the fibre.In lots of optical fiber manufacturing procedures, exact dimension of fibre size is vital for ensuring consistent efficiency and top quality. As the need for high-performance optical fibres continues to rise, the duty of size analysers comes to be increasingly essential in attaining the preferred quality and performance requirements in fibre optic systems.

These functions collectively contribute to the efficacy of fibre diameter analysers in enhancing fiber optic performance.

In verdict, the combination of optical fibre size analyser innovation is critical for making the most of fiber optic efficiency.

Report this page